HAX is holding it’s first ever demo day at our new flagship office in Newark, NJ on May 1. Below is the list of more than 30 companies that will be presenting. They were also featured in TechCrunch recently, though the descriptions below are more extended. The companies fall into a several climate and health categories, which can be navigated from the links below. For more information on demo day, click here.

Energy Independence

(13 companies)

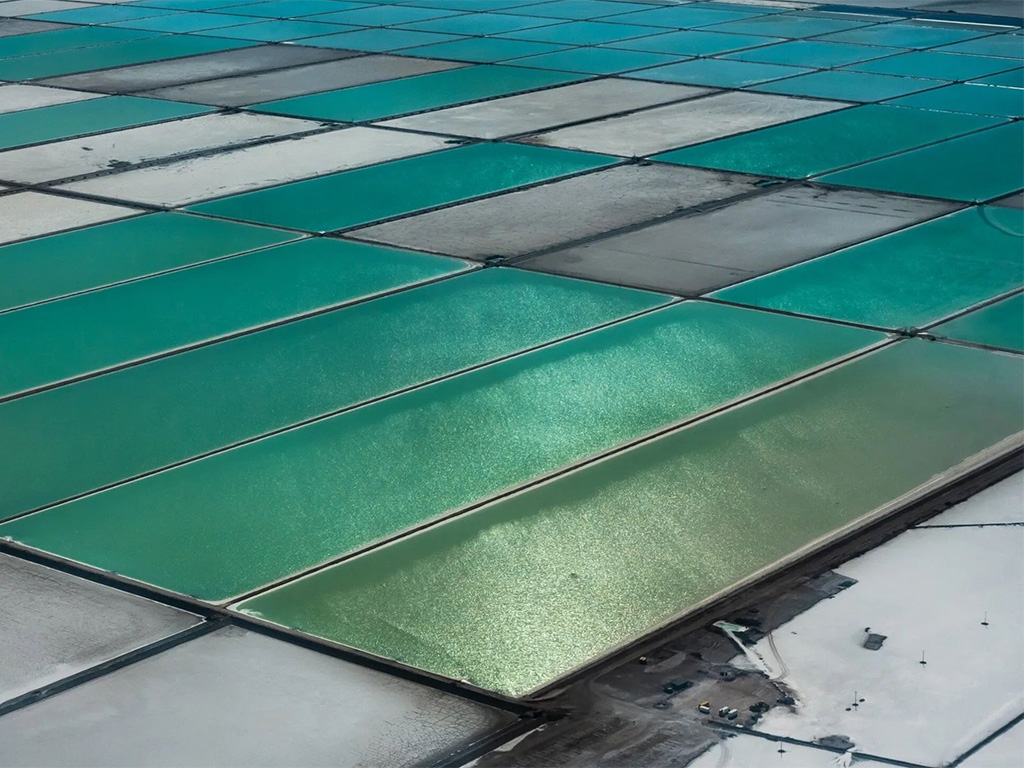

PureLi

Originating from Princeton University, PureLi has developed a pioneering approach to lithium extraction, addressing the critical demand surge anticipated as the world shifts towards electrification and electric vehicles. With lithium demand projected to double between 2025 and 2030, PureLi’s technologies emerge as essential solutions. Their initial product line enhances productivity in existing lithium evaporation ponds by 50% without necessitating new capital expenditures, aiming for full commercial deployment by the end of 2024.

Additionally, PureLi has developed a method to extract lithium from sources previously considered uneconomical, such as wastewater from fracking operations. This innovative technique allows for the efficient recovery of lithium salts, including those within the US, transforming low-value waste streams into valuable resources. PureLi’s efforts in optimizing lithium extraction processes underscore its role in advancing the sustainable production of a key resource for the future of energy and transportation.

Cool Amps

The US is facing a frightening shortfall in the critical minerals needed for energy storage & batteries to enable the shift to electrification. There are limitations in our ability to mine these locally; however we can find these critical minerals in post-manufacturing, off-spec batteries, as well as in growing reserves of post-use, spent batteries from EV’s and other uses.

But current approaches to battery recycling face a number of challenges, including complexity, cost, and energy usage to carry out reverse logistics and centralize the supply of spent materials, as well as energy intensity of the recycling processes themselves, which use high temperatures (pyrometallurgy) or toxic chemicals (hydrometallurgy) in order to separate the key ingredients within a battery back to their fundamental metal or metal salt forms, only to then utilize further energy to re-create usable cathode-active-materials.

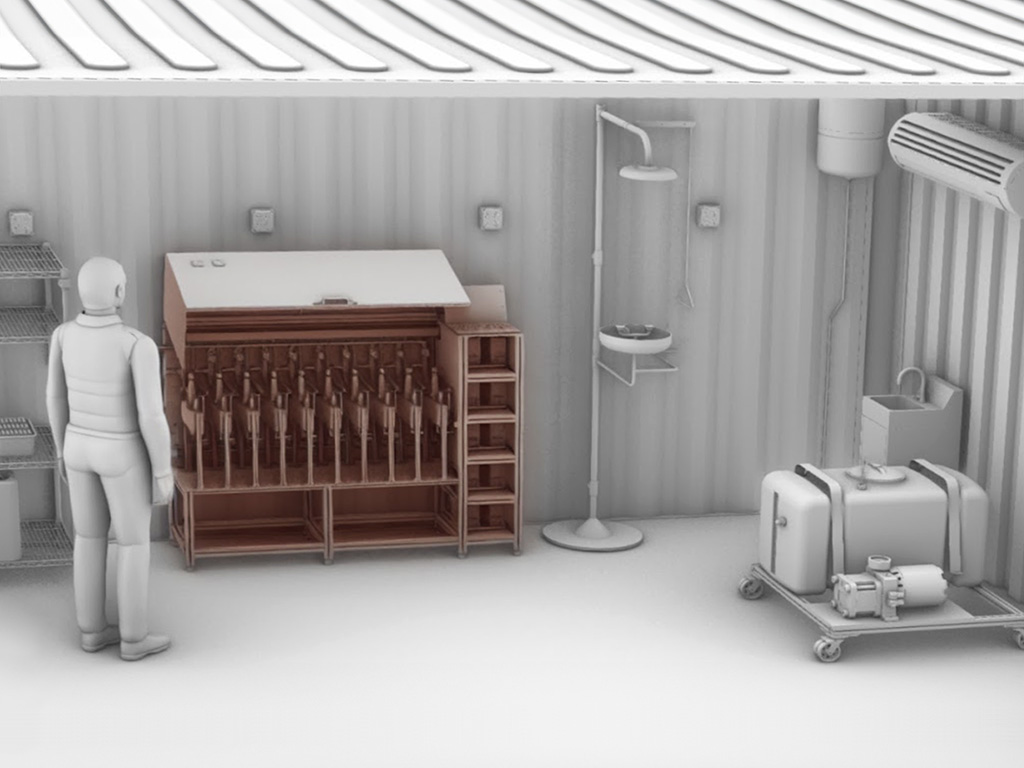

These factors combine to mean that battery recycling processes to date have struggled to chart a path to profitability, as battery acquisition & transport represent 30% of recycling costs. All of this means that we currently have sorely inadequate recovery of e-waste, with only 17% of e-waste being recovered, leaving $57 billion in unrecovered raw materials. Cool Amps has developed technology to completely disrupt this landscape, with a process that delivers greatly enhanced sustainability and profitability.

This low capex process enables distributed and localized deployment on-site alongside gigafactories to capture and regenerate any off-spec product, as well as at e-waste handlers to directly recycle spent batteries into usable cathode active materials, while at the same time recovering graphite and copper materials for reuse. To do this Cool Amps has developed an electrochemical, in-situ process that utilizes benign solvents at ambient conditions to directly extract the valuable materials, without taking them down to their component materials and having to rebuild them into usable inputs for the battery industry.

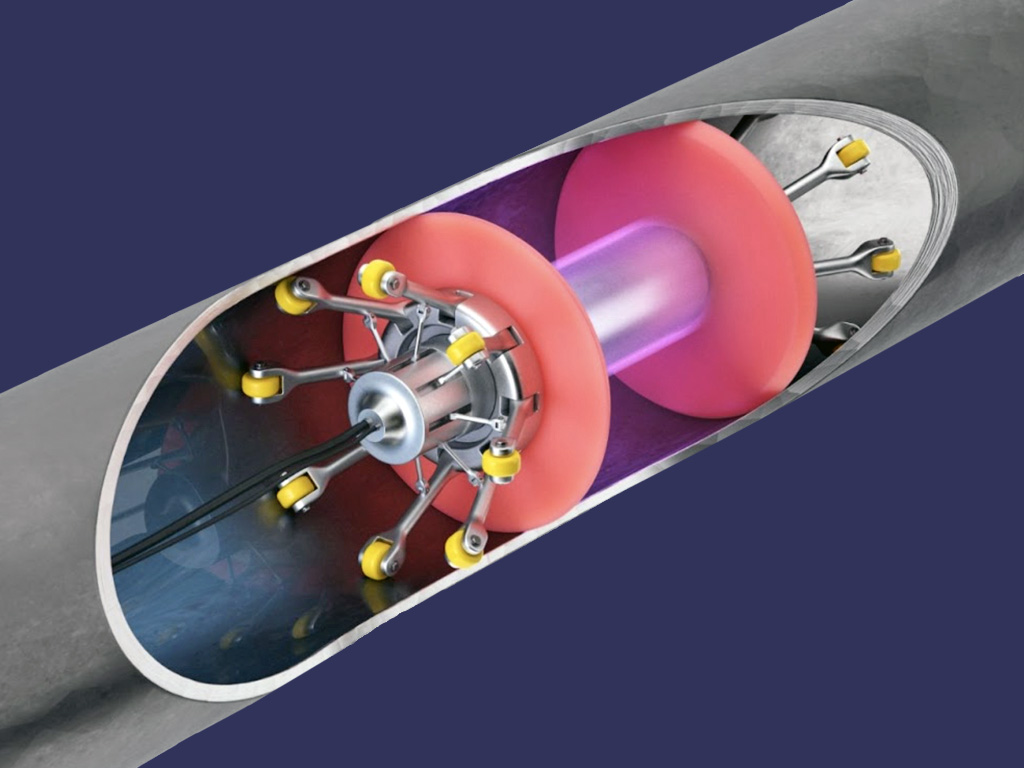

Arculus

As the Oil and Gas industry pivots towards large-scale decarbonization, the challenge of transitioning assets without compromising their remaining value becomes paramount. Arculus, leveraging research from MIT, introduces a groundbreaking coating technology that rejuvenates existing gas transmission infrastructure for hydrogen transport, whether pure or blended. This innovation presents a cost-effective method to adapt pipelines for hydrogen without the need for excavation. Arculus’s pioneering multi-layer coating is applied internally via a specially designed pigging robot.

This robot navigates through pipelines, deploying a coating resistant to hydrogen permeation, thereby extending the life and utility of these assets.

The technology facilitates the retrofitting of gas pipelines to safely transport hydrogen-natural gas blends at any concentration, effectively preventing steel embrittlement. This approach not only represents a significant cost saving for gas distribution companies by avoiding expensive infrastructure overhauls but also expedites the deployment and distribution of hydrogen, aligning with global decarbonization goals.

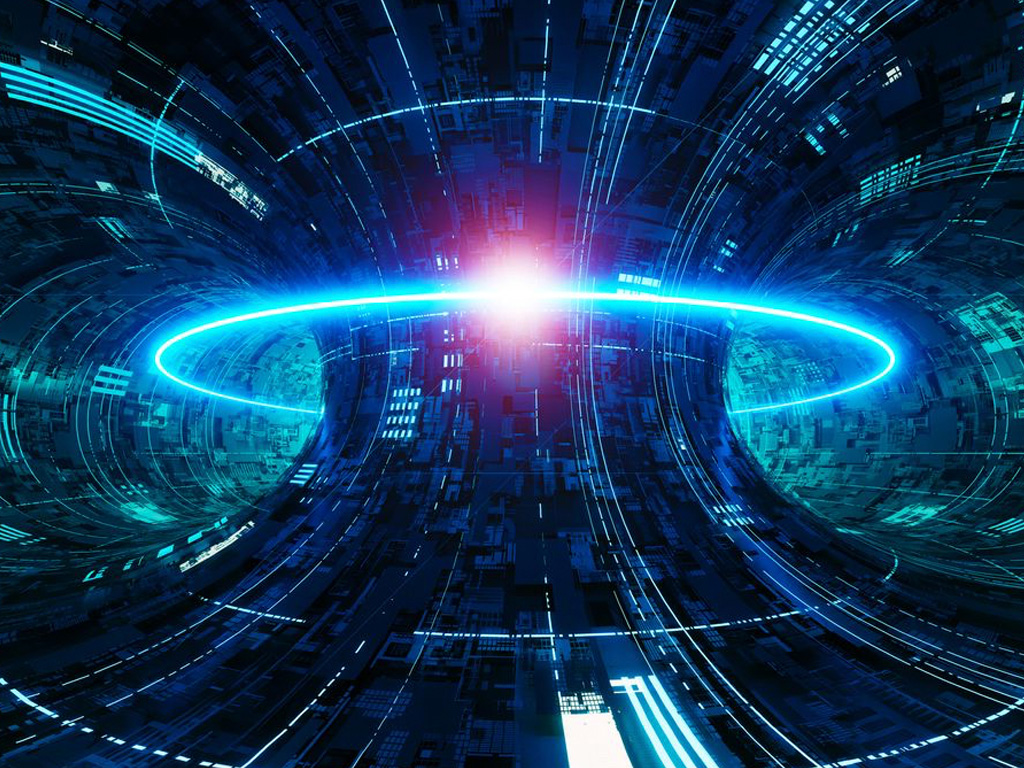

Canyon Magnet

As we look toward to 2050, global energy needs will be doubled. Fusion energy is the most promising solution and has attracted $6 billion investment over the last 5 years. The total cost of fusion reactor is around $1B, and currently magnet cost makes up half of this cost. High temperature superconductor (HTS) magnets are the key enabling technology to achieve fusion energy. They can reach 20 Tesla field and do not require costly, supply-constrained liquid helium, and can reduce the fusion reactor footprint by one third.

In total, 30+ fusion companies worldwide will need high-field magnets, and hundreds or thousands of fusion magnets will be needed in the next 3 to 5 years. Today, only handful of HTS magnets are available at the national labs; a significant supply chain challenge is in front of us. To solve this challenge, Canyon Magnet Energy is industrializing production of HTS magnets, to ensure we can produce more and better HTS magnets. Canyon Magnet Energy was founded by a former scientist at Brookhaven National Lab, who has a PhD in HTS magnets and 15 years of experience working in the field. Canyon Magnet Energy is developing infrastructure to create magnets that will be more reliable, with optimized quench protection and cooling. They are building an automated magnet production line in NJ and NY. Their technology will allow fusion companies to simply order the magnets off the shelf and achieve much-needed fusion energy sooner. Canyon Magnet aims to become the largest producer of superconducting magnets for the fusion, medical and transportation industry.

Qnetic

Meeting decarbonization targets necessitates the development of substantial grid-scale storage solutions. The use of lithium-ion (Li-ion) technology, while prevalent, becomes economically challenging for discharge durations extending beyond 4 to 6 hours. In addition, Li-ion technology suffers from degradation and decreasing performance over its usable lifetime, leading to high capital costs for replacement batteries. Addressing this need, Qnetic introduces a pioneering solution designed for discharge durations ranging from 4 to 12 hours, marking a significant innovation in energy storage with the world’s first kinetic energy storage device tailored for such applications.

Qnetic’s device boasts the capability to store 2 MWh of energy, delivering a maximum power of 500 kW at a remarkably efficient cost of $150/kWh. Their energy storage systems are also highly durable, dramatically extending the usable lifetime without meaningful degradation. This breakthrough positions Qnetic as a pivotal player in a gap within the energy storage market. By offering a solution that significantly undercuts the lifetime costs associated with Li-ion batteries, Qnetic not only enhances the economic viability of long-duration energy storage but also accelerates the transition towards more sustainable energy systems.

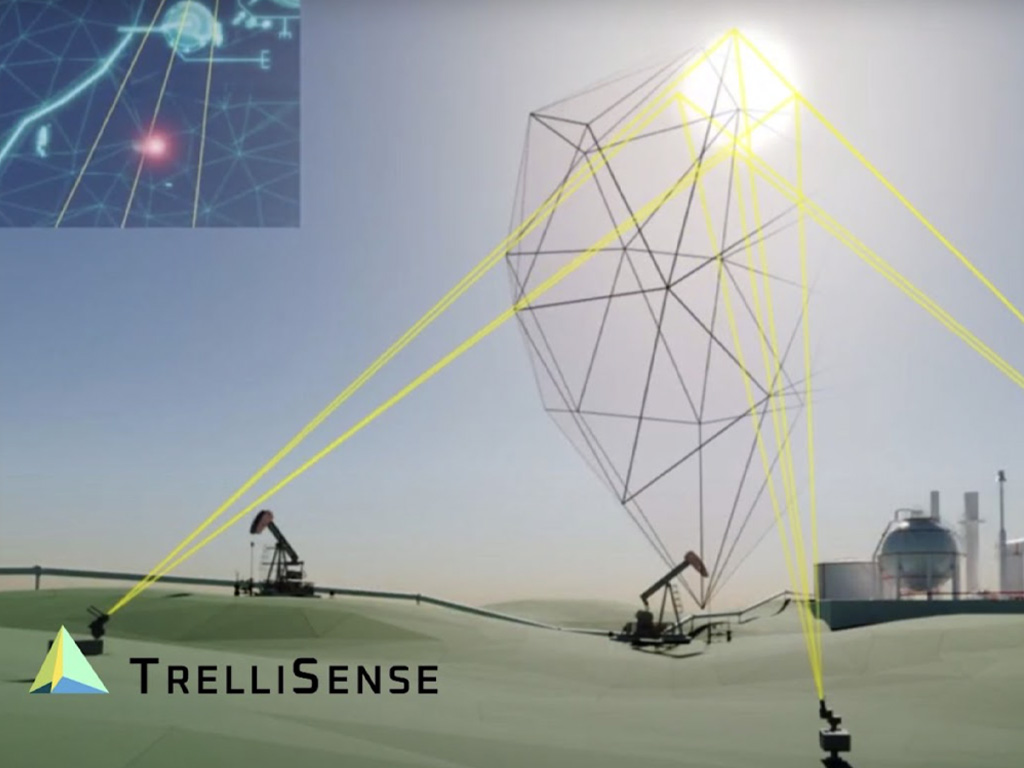

TrelliSense

Methane, with a warming potential 85 times greater than CO2, presents a critical challenge in global warming mitigation efforts. Currently, many facilities handling methane lack comprehensive monitoring systems for detecting unintended emissions within their operations. This oversight is becoming increasingly untenable due to evolving regulations, enhanced third-party and public scrutiny, and escalating reporting demands across methane-intensive sectors.

Present solutions are either constrained to intermittent data collection methods, such as drone-mounted sensors or satellite imagery, or are burdened by high costs and operational limitations, as seen with contact-based air sampling sensors which suffer from limited scope and reliability issues. Addressing this critical need, TrelliSense introduces the industry’s first solution for continuous, ground-based, and long-range methane monitoring.

These sensors enable near-real-time detection, precise localization, and accurate quantification of methane leaks across various industries including oil & gas, utilities, landfills, and agriculture. Importantly, TrelliSense achieves this at a significantly reduced cost compared to existing, more limited technologies, marking a major advancement in efforts to curtail methane emissions effectively.

Still Bright

To reach Net-Zero by 2050, the world needs to produce as much copper in the next 26 years as it has produced in all of human history. Clean energy technologies, such as wind energy, solar energy, and electric vehicles require two to five times as much copper as their traditional counterparts. Copper, however, is expected to be in short supply due to the high costs associated with the mining, concentrating, and processing of copper ore.

Currently, copper faces supply chain limitations, as 80% of copper is produced by smelting, which is environmentally damaging, highly regulated, fossil fuel dependent, and high in capital costs. Due to these reasons, the majority of smelting is carried out in China, meaning that copper concentrate is shipped globally from mine sites to be processed in China, and refined copper is then shipped to where it is needed for use – a costly and energy-intensive supply chain, leaving the US without a geopolitically secure supply of this critical mineral.

Still Bright is revolutionizing copper production with a patented electrochemical process that can replace smelting with a more efficient and sustainable alternative. The process, originally developed at Columbia University, expands copper production to currently nonviable resources, requires significantly lower capex than smelting, and can be integrated directly at mine sites to onshore production with renewable power. The Still Bright team is rapidly scaling this technology to provide the world with vast quantities of green copper.

CarbonBridge

The maritime shipping industry, responsible for approximately 3% of global emissions, mirrors the aviation industry’s environmental impact. Despite this, the sector has seen relatively little investment in ultra-low-carbon fuels, especially when viewed against the investment activity in Sustainable Aviation Fuel (SAF). Carbon Bridge is stepping into this gap by producing methanol, a key chemical and an emerging maritime fuel, derived from waste methane emissions.

Utilizing an innovative gas fermentation process, Carbon Bridge leverages a novel microbe and proprietary reactor system. This design overcomes the production rate limitations that have historically hindered gas fermentation technologies. The result is a production system that is not only highly efficient but also modular and compact, allowing for mass manufacture. These systems can be seamlessly integrated into existing methane-emitting facilities, such as wastewater treatment plants, offering a scalable solution to produce methanol. This approach not only contributes to reducing the maritime shipping industry’s carbon footprint but also valorizes waste emissions, representing a significant stride toward cleaner maritime operations.

Mitico

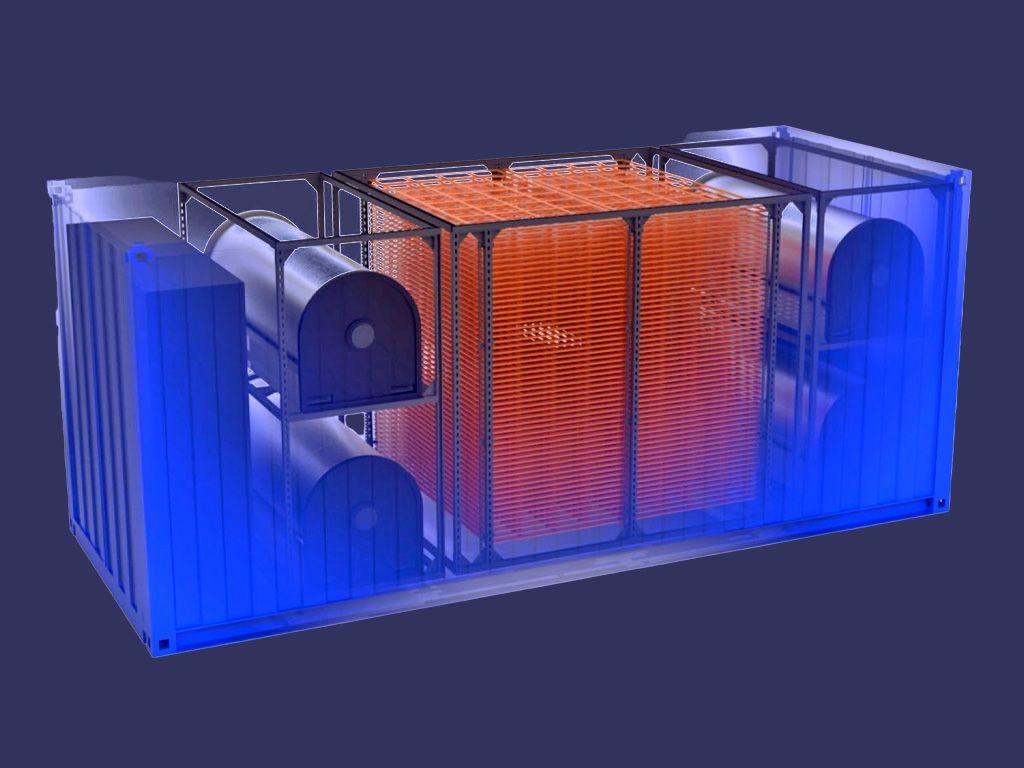

Many legacy industries present large challenges to decarbonize, and at the same time are needed to fulfill global energy demands in the short term. These include natural-gas and wood fired burners and gas-fired power plants. Existing carbon-capture media, such as amine-based sorbents, face challenges to effectively sequester carbon dioxide emitted from these heavy industrial uses.

Mitico offers state-of-the-art services and equipment to capture carbon dioxide (CO2). Their patent-pending granulated metal carbonate sorption technology (GMC), developed at Caltech, captures over 95% of the CO2 emitted from post-combustion point sources (flue gases), including gas-fired power plants and boilers, and waste-to-energy and biomass-to-energy facilities. They enable carbon capture, utilization, and storage (CCUS) as a service at a low cost, reaching prices below $50/ton.

The Mitico technology is based on using abundant, cost-effective, and low-impact GMC sorbents. The GMC solid can be rejuvenated through moderate temperature- and pressure-driven swing sorption-desorption cycles. The extracted and purified (99.9%) CO2 can be sequestered or used as a feedstock for green chemistry. The Mitico process is scalable, applicable to small (1K CO2 tonne/year) natural-gas and wood fired burners all the way to large (>100K CO2 tonne /year) gas-fired power plants and hard-to-decarbonize industries.

Metal Light

Despite their widespread use, diesel generators are noisy, emit unpleasant odors, and contribute significantly to environmental pollution. In fact, they release more than double the CO2 per kilowatt delivered compared to the average US grid emissions—a discrepancy poised to widen as the grid becomes increasingly cleaner. In response to these challenges, Metal Light has introduced a groundbreaking, eco-friendly alternative to conventional diesel generators.

Their innovative technology harnesses the power of energy-dense metal as fuel. The electricity generation process is not only less expensive than diesel but is also quiet, odor-free, with the only emission being low amounts of hydrogen—a valuable byproduct in itself. Remarkably, Metal Light achieves this with a cost of power delivery that undercuts traditional diesel generators. This development represents a significant step forward in providing cleaner, more sustainable, and cost-effective power generation solutions.

Renewell

Currently there are over 2 million idle and orphan oil wells in the US, representing a $400B liability to oil & gas companies to clean up these sites. At the same time, the US needs to increase energy storage by 10x to enable full utilization of renewables like solar and wind. Renewell turns these oil & gas liabilities into the cheapest long-duration energy storage system since stored hydro.

They convert idle oil and gas wells that have reached their end of life into gravity energy storage devices. Customers want this because it saves them money compared to traditional plug & abandonment, and they receive rental revenue on a previously idle well. Renewell is addressing a $287B total addressable market, and are already piloting these solutions in California.

Altiro Energy

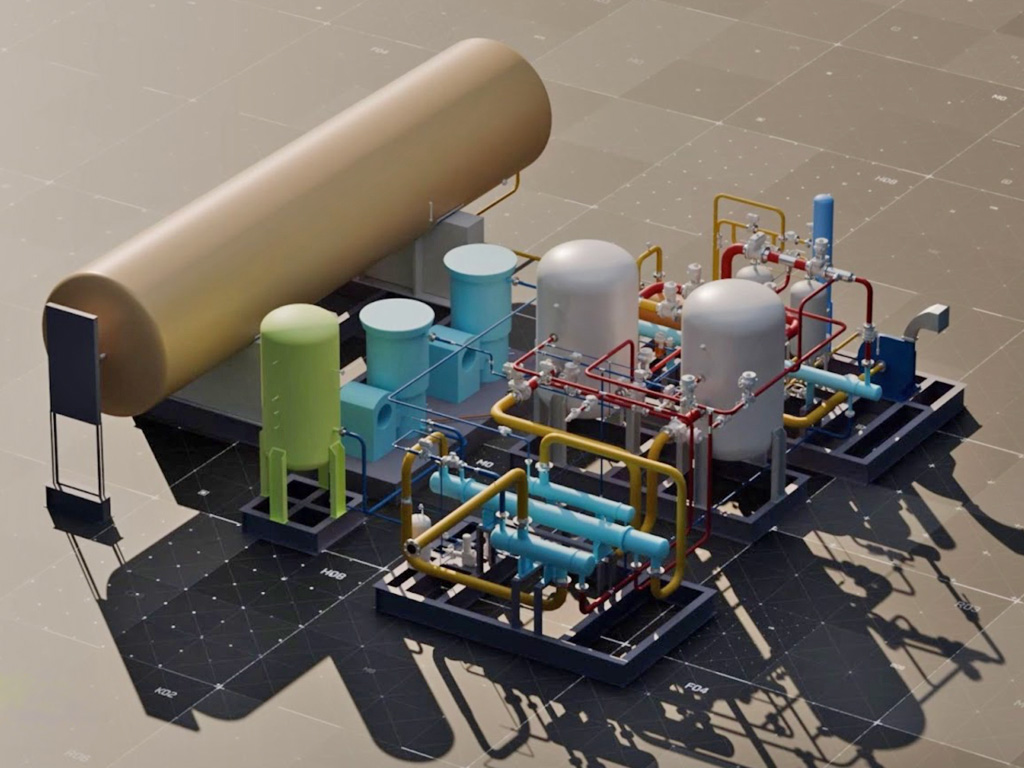

The transition to low carbon, behind-the-meter power generation at industrial facilities is fraught with challenges. Such systems must not only be highly reliable and capable of operating at a large scale, but they also need to supply high quality and high temperature process heat, often in the form of steam, which is hard to achieve with renewable energy sources. Moreover, the remote locations of many of these facilities compound fuel delivery and storage difficulties.

Altiro presents a breakthrough iron-fuel and reactor system that creates zero CO2 emissions during power generation. This innovative solution seamlessly integrates into existing heat and power infrastructures, offering a cost-competitive alternative to current low carbon technologies while ensuring high reliability. The iron-fuel system allows for the on-site storage of substantial energy reserves, effectively mitigating logistical issues and enhancing facility resilience against weather-related disruptions that could affect renewable energy supplies. Altiro’s technology addresses the complex energy needs of industrial facilities, paving the way for a more sustainable and dependable power generation landscape.

SWAP Robotics

Utility-scale solar power is on-track to become the world’s #1 energy source by the 2040’s. SWAP robotics addresses two significant cost challenges to the CapEx and OpEx of solar farms with automated solutions. In the utility-scale solar construction phase, SWAP is focused on the single biggest labor expense: solar panel laying.

In the following 30-year Operations & Maintenance phase, they also solve the single biggest expense: cutting the grass & vegetation on 1,000+ acre sites.

Each of these activities cost over $10 million throughout the lifetime of a typical utility-scale solar site. Their robots for solar panel laying and vegetation management at large solar farms drastically reduce install costs and continuing O&M. SWAP already has dozens of robots deployed already on half a dozen solar sites, and are on-track for over $3M of revenue in 2024. Solar additions will be 58% of new electricity generation in the USA this year, and utility-scale solar is typically a site bigger than 500 acres in size, and 80% of new solar energy in the USA coming online is from utility-scale solar.

At the same time, solar is now 29% cheaper than any other form of new energy build-out in the USA. For these reasons, utility-scale solar is on-track to become the world’s #1 energy source by the 2040s, and SWAP is poised to enable and serve this massive industry.

Health

(8 companies)

PDS

The fentanyl crisis is tearing the US apart, taking lives and destroying communities. Real-time testing that can deliver quantitative results ensures that harm and loss of life can be minimized. Portable Diagnostic Systems (PDS) is addressing this immediate need for rapid onsite diagnostic testing and toxicology in a variety of markets, including emergency medicine, roadside drug screening, cause of death investigation, and many others.

The global TAM for point-of-care in vitro diagnostic testing is ~$50bn and forensic toxicology is ~$12bn. PDS has developed technology to enable rapid, small scale, multiplex analytics, delivering laboratory quality results on-site in real time. Using this technology they’ve built their first product, the Integrity-1 Analysis System, which is a portable ‘lab-in-a-box’ solution for clinicians and investigators that streamlines diagnostic and toxicology testing, saving time and money, while delivering impactful results.

This system is highly portable and rugged, and can collect samples within seconds, and provide actionable test results in minutes. Their first application is creating the world’s most comprehensive on-site, real-time drug test for use in roadside drug testing. They have garnered great interest and engagement with law enforcement agents, looking to purchase next-generation tools to ensure they are equipped to address drug and alcohol abuse in the field.

LightHearted

One in two people over age 65 have an undiagnosed heart valve disease. This leads to hundreds of thousands of individuals per year being diagnosed in critical condition during a hospital admission or, worse, at autopsy due to poor diagnostic accuracy in primary care, as well as billions of dollars being spent yearly to treat heart failure that was not detected via early diagnosis, thus missing the key window of opportunity for preventative care.

LightHearted has developed an advanced, laser-based digital stethoscope, which is a non-invasive solution to accurately diagnose valve diseases within the primary care setting in just 10 seconds. The device automatically acquires data from the patient from a distance, non-invasively, and without the need for patient or clinician input. LightHearted’s AI platform reads the data to produce a diagnostic report in 1 minute and relay it to the relevant clinicians. This solution can detect novel biomarkers to enable early diagnosis, and the opportunity for management with pharmaceutical intervention, and therefore can save billions of dollars annually on heart failure treatment.

LightHearted’s solution opens the door for dramatically improved triaging, lowering wait time, and reducing the need for echocardiogram & other, more costly diagnostics. The technology was developed during the co-founder & CEO’s PhD degree in AI and Biomedical Devices. LightHearted is initially piloting with the National Health Service in the UK, and collaborating with clinicians to validate their device in real patients.

Lura Health

Americans and humans globally are facing multiple health crises, as they are plagued by chronic disease, which require consistent tracking in order to provide effective treatment. Generation of continuous data for monitoring and controlling these diseases is essential, as single-point tests do not effectively measure long-term trends, cannot provide early, proactive alerts, and do not enable measurements of efficacy of preventative measures.

The world is calling for a non-invasive medical wearable to address these challenges, and salivary diagnostics have emerged as an exciting solution, and are now approaching a growth inflection point. In order to bring this promising approach to continuous, real-time monitoring to life, Lura Health has solved a monumental engineering challenge and developed the world’s first salivary diagnostic wearable. To achieve this breakthrough, the team invented 5 custom components and leveraged the latest pre-market advances from top companies, and they developed microscale assembly processes to fit a full IoT system on a tooth.

This technology can be easily integrated into existing devices, such as retainers, implants, and dentures. Lura’s sensors are implemented in the mouth, providing real-time, continuous data that is sent to a patient’s smart phone, and shared with their doctor. Their first go-to-market opportunity is within dental applications, where the sensor will be used to monitor acid as a warning sign for tooth decay. They are also pursuing medical applications, starting with glucose monitoring for diabetes and electrolyte monitoring for chronic kidney and cardiovascular disease.

Openshelf

We are currently facing large labor shortages across healthcare. Despite increasing demand for healthcare, there is insufficient growth of labor, and in fact there has been a 5% per year drop in healthcare labor force.That is why Open Shelf is developing low-cost, AI-automated inventory management for healthcare.

Open Shelf technology will free up clinicians’ time, so that they can focus on patients, rather than inventory management. Open Shelf combines modular, scalable robotic automation with intelligent control to deliver an automated robotic retrieval & restocking solution. This enables real-time inventory data, predictive reordering, all while reducing labor requirements, increasing operational consistency, and eliminating overstock and wastage. Founded by Chiu Chau, 3x founder & roboticist. Chiu previously founded & led OpenTrons, a YC-, HAX-, and Khosla-backed company to a $1.8B valuation.

Aurasense

Currently, neurological conditions are diagnosed using very subjective criteria, creating multiple problems, including inaccurate, unhelpful diagnoses. In addition, getting meaningful feedback requires in-person consultation with specialists, which severely limits access to care for those in more remote and underserved areas.

Aurasense quantifies neurological conditions by creating point-of-care devices to capture and analyze motor function and provide data-enabled & digitized treatment feedback, across a range of neurological conditions. Their advanced tool will enable democratized and improved diagnosis and care. Their first application will be to utilize the tool in clinical trial enablement, to accelerate and improve validation of treatment candidates for neurological diseases. This will address the existing challenge that many promising drug candidates end up failing at later stages of clinical trials, in large part due to subjective and uncorrelated performance data.

OLI

There are nearly 1 million end-stage kidney patients in the US. And while going to the hospital or center for dialysis is an inconvenience and major disruption to their daily lives, only 1 in 50 patients currently opt for in-home dialysis. This is because current options for in-home dialysis are unpleasant and impractical to use.

They are large and obtrusive, they force patients to be stuck in their homes for extended periods, and they are very complex to operate. Oli is building a better future for these patients, by creating compact, portable, and intuitively operated dialysis systems, so that these patients can get their lives back again. Oli’s core technology has been developed around a novel sorbent that enables this huge step forward in miniaturization and simplified operation. They will begin initial deployment of their MVP in the clinic, in order to accelerate regulatory approval for patient use in-home or on-the-go.

Pons

PONS is disrupting the $100B clinical trial and biomarker industry by converting any mobile ultrasound into a powerful data source. Currently the healthcare system is limited by some major blind spots: 90% of clinical drug development fails, and we fail to collect high-quality, large-scale data on early-stage disease.

PONS is solving this problem by converting any mobile ultrasound with AI into a powerful high-quality data source. PONS takes point-of-care ultrasound beyond imaging and turns it into a data engine. This ensures that capturing of data on healthy samples, as well as those in early- and later-stage disease can be captured and utilized. Imagine pharmacies and retail stores becoming mini-imaging hubs. Using PONS’s AI-powered pods, rich data can be gathered that fuels drug development, personalized medicine and accelerates the timeline for life-saving treatments.

DIA

Cortisol is the gold standard in detecting human health & well-being. Cortisol is a steroid hormone made by the kidneys that is commonly referred to as “the stress hormone.” Measurement of cortisol levels to determine stress is currently done via methods that are painful (blood samples), slow (requiring samples to be sent to the lab for analysis), and costly. DIA is creating a new standard in biomarker monitoring.

DIA is on a mission to improve human health by measuring chemical threats daily, in real-time, and at the point-of-need. They use groundbreaking electrochemical sensing technology integrated into wearable devices. These devices enable them to measure cortisol in real time, continuously, non-invasively, and affordably. The market for solving stress is a $300B opportunity. DIA is already working directly with the US Army via a $1.9M SBIR grant to develop and pilot their devices, and is pursuing early adoption with pro and elite athletes, as well as developing applications in healthcare to improve real-time monitoring of human health.

Built Environment

(7 companies)

Algoma

In the face of a significant housing shortage and sustainability crisis, the real estate development sector struggles with inefficiency and escalating costs. Conventional construction materials significantly contribute to embodied carbon, with the built environment responsible for 40% of global greenhouse gas emissions. Traditional design approaches often lead to bespoke, one-off projects with little incentive for efficiency due to time-based contracts.

Hence, there is a huge opportunity for a housing solution that is repeatable, sustainable and scalable.Algoma is a digital architect and engineer that provides real estate developers with a faster, cost-effective, and sustainable approach to housing. Leveraging mass timber and a library of standardized building components, Algoma’s innovative software platform automates the design phase and offers automated feasibility studies, allowing developers to understand what’s possible on site, providing them with accurate cost estimates very early on. Integrated architectural and engineering designs, allowing real estate developers to move from concept design to construction documentation faster and at lower cost. Connection to contractors and suppliers, allowing developers to efficiently find partners to deliver the project.

MIMiC

Heating and cooling make up the majority of energy consumption in buildings, representing over 40% of energy-related greenhouse gas (GHG) emissions. Originating from extensive multidisciplinary research at Rensselaer Polytechnic Institute, MIMiC Systems is pioneering a technology aimed at reducing the emissions from refrigerants in traditional vapor-compression systems, while enhancing thermal comfort without incurring energy penalties.

MIMiC employs advanced solid-state heat pumps, known as thermoelectric devices, combined with innovations in power electronics and controls. This approach not only boosts system efficiency but also fully eliminates the need for environmentally harmful refrigerants. The technology is particularly advantageous for retrofitting residential buildings, streamlining the installation process to save both time and labor costs. Moreover, by significantly reducing the number of moving parts, MIMiC’s solution extends the operational lifetime of heating and cooling systems, marking a significant step forward in reducing the environmental impact of building climate control.

CocoonCarbon

The steel and cement sectors stand as two of the most significant contributors to global greenhouse gas emissions, presenting considerable challenges in their journey towards decarbonization. Cocoon Carbon introduces an innovative solution that not only aids these industries in reducing their carbon footprint but also opens new avenues for revenue generation, particularly for steel manufacturers.

By harnessing steel slag, a byproduct of electric arc furnaces, Cocoon Carbon offers a novel method to repurpose this waste into a low-carbon, economically valuable alternative to traditional cement. This approach allows two industries challenged by the economic hurdles of decarbonization to collaborate and profit. For steel manufacturers, it valorizes a previously underutilized waste product and integrates carbon capture into the slag’s upgrading process, effectively turning a cost center into a profit center. Meanwhile, the cement industry benefits from access to a sustainable input that lowers the carbon intensity of its products. Cocoon Carbon’s technology exemplifies how environmental sustainability and economic viability can align, delivering mutual benefits to industries at the forefront of the decarbonization challenge.

Verdex

Filtration media represents a $100B climate problem. Current materials are filled with harmful microplastics and polluting forever chemicals, and they are low performance while at the same time high cost. These filters are used across industries: for indoor air filtration within HVAC systems, for chemical separations, CO2 capture, and within lithium-ion batteries.

Verdex has developed a highly scalable and eco-friendly nanofiber manufacturing process to produce advanced filtration materials. They are able to use bio-based and biodegradable materials that do not shed microplastics or contain forever chemicals. Their process enables production of materials that can drop into existing filtration systems and provide solutions that are high performance and lower cost. In HVAC applications, Verdex materials are able to deliver improved air filtration, while at the same time lowering energy consumption by 50%. These materials also have longer lifetimes. Verdex’s unique process technology provides materials that can be used for energy efficient HVAC, CO2 capture, and green battery components.

Renovate Robotics

The US is facing a massive labor shortage, which has dramatic implications to new home construction, repairs to existing units in case of damage due to ever-increasing storms as a result of climate change, and also severely delays further deployment of rooftop solar. Climate is causing increasing damage, with over 20 annual climate-related events causing >$1B worth of damage, up from less than 5 such events per year, just 25 years ago.

Roofing work in particular is an undesirable and dangerous task, leaving major gaps in workforce and creating further backlogs in roofing construction. Renovate is automating roofing and solar installation. They have built Rufus, an automated robotic roofing system which is able to install shingles and solar shingles on residential homes. Rufus installs shingles and delivers consistent quality, thus increasing the productivity, safety, quality, and speed of roof installation. The Rufus system adapts easily to different roof geometries, and is designed to run autonomously, requiring only a single human operator to monitor it and refill materials. They have built a full system prototype, carried out internal testing and have piloted with initial customers, and are planning for contractors to begin leasing robots in the summer of 2025.

Terran Robotics

The United States is grappling with a significant housing shortage, with the rate of new home construction still trailing behind the pre-2008 financial crisis levels. The scarcity of new housing, coupled with high costs stemming from a limited labor pool and fluctuating raw material prices, exacerbates this issue.

Terran Robotics offers an innovative solution by employing one of the most ancient and abundantly available materials – clay – to build adobe homes. Despite its raw material being exceptionally low-cost, adobe has evolved into a luxury building material due to the labor-intensive construction process.Terran Robotics is revolutionizing this sector by automating the construction of adobe homes. This groundbreaking approach not only streamlines the building process but also significantly reduces costs, making what was once considered a premium housing option accessible to a broader audience. Through automation, Terran Robotics is addressing the critical need for affordable housing while simultaneously breathing new life into one of humanity’s oldest building materials, offering a sustainable and cost-effective solution to the current housing crisis.

Amatec

While essential to building the structures that enable and improve our everyday life, concrete is responsible for a whopping 8 percent of global carbon emissions; 90 percent of these emissions come from the production of cement, the primary strength-contributing ingredient of concrete. Amatec seeks to change this, with their revolutionary technology that enables production of high-density gypsum (HDG), which can be made simply and quickly, and they have demonstrated can match or exceed the performance properties of concrete, with a far lower carbon footprint.

While existing processes to make gypsum require excessive amounts of water to ensure proper fluidity during the mixing step, which yield a weak material commonly used in drywall applications, Amatec’s founders have discovered an approach that allows them to use just a stoichiometric amount of water, yielding a strong, structural material with high compressive strength. Their HDG materials cure within minutes, can be made at lower cost than concrete, and also provide up to 60% lower embodied carbon than concrete. They are currently building capabilities to begin delivering their technology to the pre-cast and residential prefabrication markets.

Advanced Compute

(2 companies)

Hyperlume

AI is already creating a huge electricity burden, with data centers that today consume more electricity than Western countries like the UK, and this is set to grow exponentially. Currently, copper interconnects are used to transmit signals, and 40% of this energy utilized is wasted as heat in copper wire. Hyperlume has developed a patented micro-LED structure, light coupling method, modulation and ultra-low power receiver circuit.

Their technology enables high-speed, ultra-low-power, low-cost optical interconnects for data centers and high-performance computing systems that can save up to 10% energy. Hyperlume is initially deploying their technology as energy-efficient, ultra-fast, cheap Active Optical Cable, followed by application to very short range link and Seamless Optical Fabric/Chiplet in 2025. They have significant market traction with industry leaders including Google, Cisco, Samsung, and Intel, among others.

MesaQuantum

GPS stands as one of the most remarkable innovations of our era, transcending its use case as a navigation tool to become the global reference for time. Utilizing GPS for position, navigation, and timing synchronization in crucial systems such as data centers, the energy grid, and consumer electronics has become indispensable to our economy. However, as our dependence on GPS grows, geopolitical tensions and the rise of new technologies like autonomous systems are exposing its limitations.

Governments worldwide are now seeking alternative solutions. Enter MesaQuantum: we’re developing next-generation chip-scale atomic clocks that aim to reduce our critical reliance on GPS, while ensuring we have GPS capabilities all the time…everywhere. MesaQuantum has developed a low cost, chip-scale atomic clock that can seamlessly be integrated into existing electronic boards. They do this through a quantum technology developed at the University of Colorado, Boulder, which is one of the world leading universities in Quantum technologies. Their chips are 10 times better, 10 times smaller and 100 times less expensive to manufacture than the state of the art technologies in this critical time keeping application.

Advanced Manufacturing

(8 companies)

3DK Tech

Metal additive manufacturing has traditionally been confined to prototyping, hindered by the mechanical properties and low reliability of printed parts, which rendered them unsuitable for direct replacement in high-demand sectors such as aerospace and automotive. However, 3DK Tech, emerging from research at the Hong Kong University of Science and Technology, is breaking new ground with a metal additive manufacturing process that elevates printed metal alloy parts to the mechanical performance levels of their conventionally manufactured counterparts.

This advancement, achieved through 3DK Tech’s innovative use of ultrasonic vibration techniques, significantly enhances the mechanical properties of printed parts. Such an improvement opens up opportunities for maintenance and repair operations across automotive, energy, and aerospace sectors to streamline their part inventories, leading to considerable time and cost savings. Furthermore, 3DK Tech’s process facilitates the swift production of parts that are either out of production or subject to long lead times because of the need for specialized tooling, offering additional financial and operational benefits to these industries. This development represents a significant leap forward in making metal additive manufacturing a viable option for high-performance applications.

Silana

Fashion is the second most polluting industry on the planet, trumped only by the oil and gas industry. Despite technological advances elsewhere, garment production remains basically the same as 50 years ago with 100% of garments still made by hand. Because of this and the extreme price sensitivity, fashion manufacturers are forced to carry out production in geographies where labor is incredibly cheap.

This leads to exploitation and poor working conditions for workers, as well as a very long, complex, costly, and energy intensive supply chain. The sad result: 93% of workers don’t earn a living wage and 30% of all clothes are never sold at all! Silana is solving these challenges, and they have developed the very first robot that fully automates the outdated, manual, and cost-intensive sewing process. This technological innovation enables cost-effective, fast, and sustainable production without any overproduction, thus allowing brands and manufacturers to realize localized production at competitive cost. Silana’s technology means that clothing can be produced in the United States at lower cost than China. Their standout capabilities have gained recognition from the market, and are already driving excitement and significant traction within the apparel industry and beyond, from highly esteemed brands and manufacturers.

Livin Farms

Livin Farms has figured out a fundamentally more efficient and sustainable way to produce protein for the animal feed industry. Livin Farms empowers its customers to produce insect-derived protein, oil, and fertilizer from food waste, thus reducing CO2 emissions by 92% vs conventional protein production via animal agriculture.

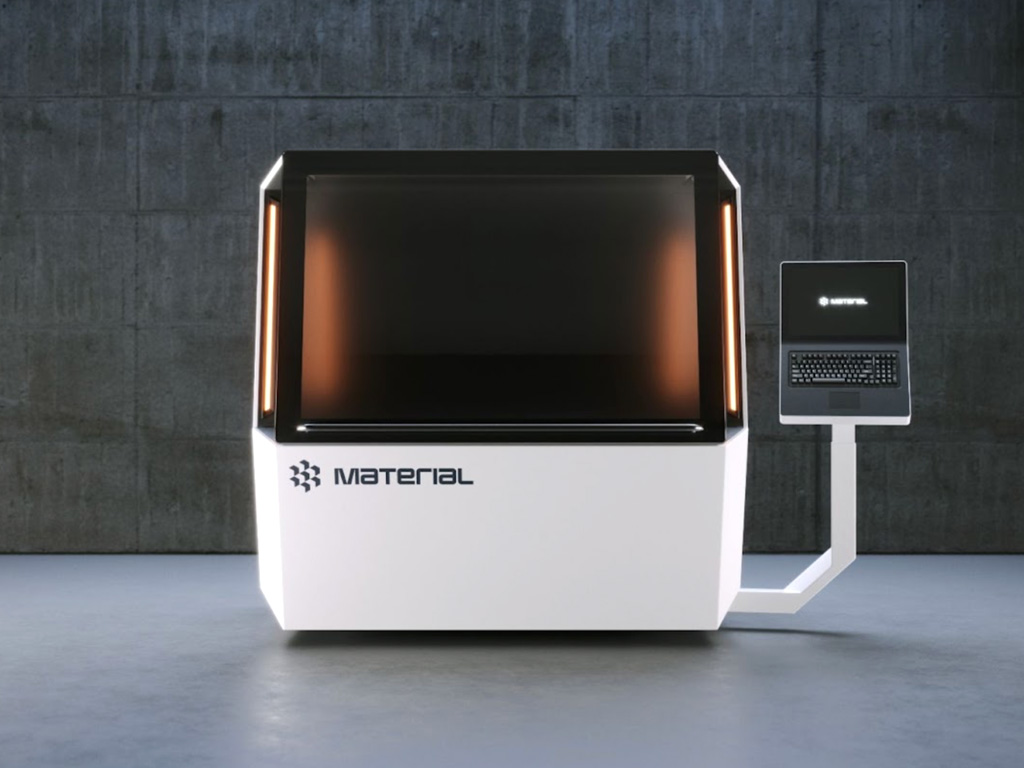

Material

Despite the influx of funds into the space, current battery manufacturers face limitations that prevent true innovation. This limits innovation into new battery materials, keeping us dependent on the same set of raw materials, and it also limits innovation on design and thus improvements to battery weight, shape, and performance. Material is looking to move beyond these limitations, and have developed technology to enable the custom 3D printing of high-performance batteries at scale.

This allows them to print batteries of any shape, any size, and with more integrations. Material’s technology has many advantages, such as providing ability to make fully customizable batteries, tailored to any specification; creating highly powerful batteries, with up to 300% more capacity; creating batteries that use 15% less space and can fit any application shape and have improved safety, with 20% cooler operating temperatures; and have 75% fewer fabrication steps. They are able to achieve this at less than half the cost of other battery manufacturers, at an estimated $65/kWh. Material’s 3D printing approach to battery design and manufacture is superior in every way to roll-to-roll technology, providing simplified manufacturing, batteries with high volumetric energy density, and limitless 3D geometries. They have already successfully printed first generation custom 3D batteries, and are currently building their full-scale hybrid printer, and are well on their way to establishing the new standard for battery technology.

AtoMe

To support a world desperately seeking clean energy, materials innovation needs to match the pace of design innovation. Applications such as nuclear power, aerospace, wind energy, traditional energy & thermal power, can all benefit from materials with enhanced operational performance. Specifically new structural materials are needed with higher temperature tolerance, enhanced strength and toughness, robust corrosion resistance, and improved radiation survivability.

MIT spinout company AtoMe has developed a platform approach to accelerate and improve the pace and results of material development, utilizing a technique of rapid enhancement with nano-reinforcement. Metal materials augmented with ceramic additions can achieve powerful improvements in mechanical and thermal properties. Modern 3D printing opens the door both to rapid iteration to create exciting new material combinations and scalable production of these composites for the first time. AtoMe has already developed a new material with improved properties versus existing alloys used for highly demanding nuclear applications. This first material has 15% higher ultimate tensile strength, over 100 degree C increase in upper temperature limit, 5x decrease in embrittlement due to radiation, and 20% higher hardness. By improving grain structure and adjusting compositional chemistry with robust ceramic nano-precipitates, AtoMe can achieve property improvements for a variety of base metals at both room temperature and high temperatures, while choice and concentration of additive add an extra layer of tunability to produce a material uniquely suited to the needs of the end-user.

The team is currently scaling production to enable sampling across a variety of industry applications.

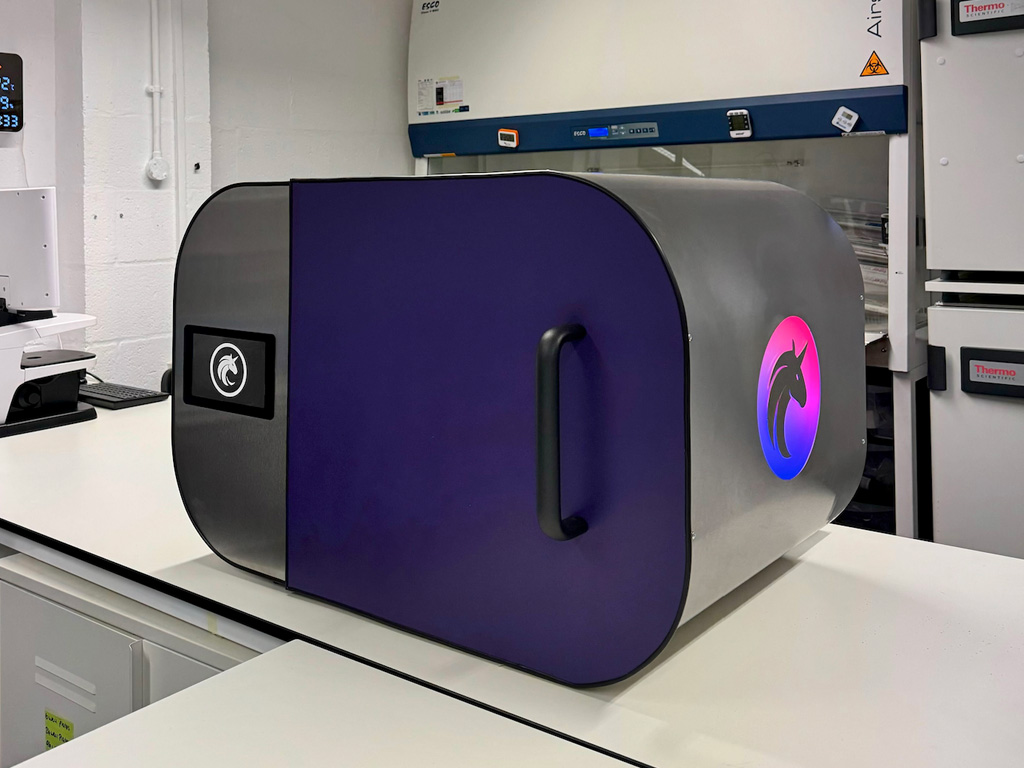

Unicorn Bio

Unicorn Biotechnologies is accelerating science & technology to power the rapidly growing, trillion-dollar bioeconomy. Mammalian cells are the building blocks for transformative markets. From extending human healthspan and combating ageing itself (longevity) to creating potentially curative cancer treatments (cell & gene therapies), growing replacement tissues and organs (regenerative medicine) and developing new food sources to feed a growing population (cultivated meat), mammalian cells provide potential solutions to all of these challenges.

However, the process of growing mammalian cells hasn’t significantly changed since the 1950s. Non-industrial production methods are highly manual and labor intensive, and remain artisinal in nature. This slows down the pace of R&D and creates significant barriers to scaling breakthrough innovations like potential cures and new protein sources to nourish people. Non-robust processes with high batch failure rates and multi-year tech transfers can mean a cost of hundreds of thousands of dollars to make a therapeutic intervention for a single person. Unicorn is solving these challenges by developing a platform to industrialize the production of mammalian cells and seamlessly scale processes from benchtop to commercial production. They leverage advanced industrial control, fluidics, biochemical-based sensing and artificial intelligence-driven adaptive process control systems to create machines that reduce labor (80%+), variability (50%+) and production costs (25-50%+) of manufacturing mammalian cells.

Our modular, automated systems are linearly scalable and fully digitized, removing the need for tedious tech transfers, reducing costs, dramatically shortening timelines, and saving space when scaling from lab to commercial manufacturing. They are optimizing for near-term revenues by pursuing technology licensing (selling engineered cell lines) while building out capabilities to provide “Cell-manufacturing-as-a-Service” to customers in cell and gene therapy, as well as pharmaceutical and cultivated meat markets. Ultimately, Unicorn is building the picks and shovels that will be used to power the century of biology.

Mazlite

Spraying and coating is a 220+ billion dollar market. From cars to crops, from boats to batteries – spraying is a critical operation in many multi-billion dollar industries globally. But today’s practices are far from perfect. Specifically, current spray processes for automotive are highly inefficient.

These processes are high in cost, making up 30% of OEM operating costs; inefficient, with 30% of paint solids being wasted; riddled with quality issues, where 25% of parts have painting defects; all of this together leads to massive environmental Impact, making up 65% of OEM plants’ emissions. Mazlite has built a unique solution to these challenges, and is transforming the industrial spraying and coating industry with predictive quality control through physics-based AI, inline sensors, and advanced process digitization. Their solution elevates product quality, enhances sustainability, improves efficiency and lowers energy usage.

Mazlite is transforming the industry by providing a pre-application spray monitoring and digitization solution. With their physics-based AI, they’re shifting industries from reactive corrections to proactive control. Data gathered through their pilots with major automotive OEMs has demonstrated that they enable global savings of $12.9B per year based on cumulative decreased spending on labor, down time, reduced defects, and reductions in waste.

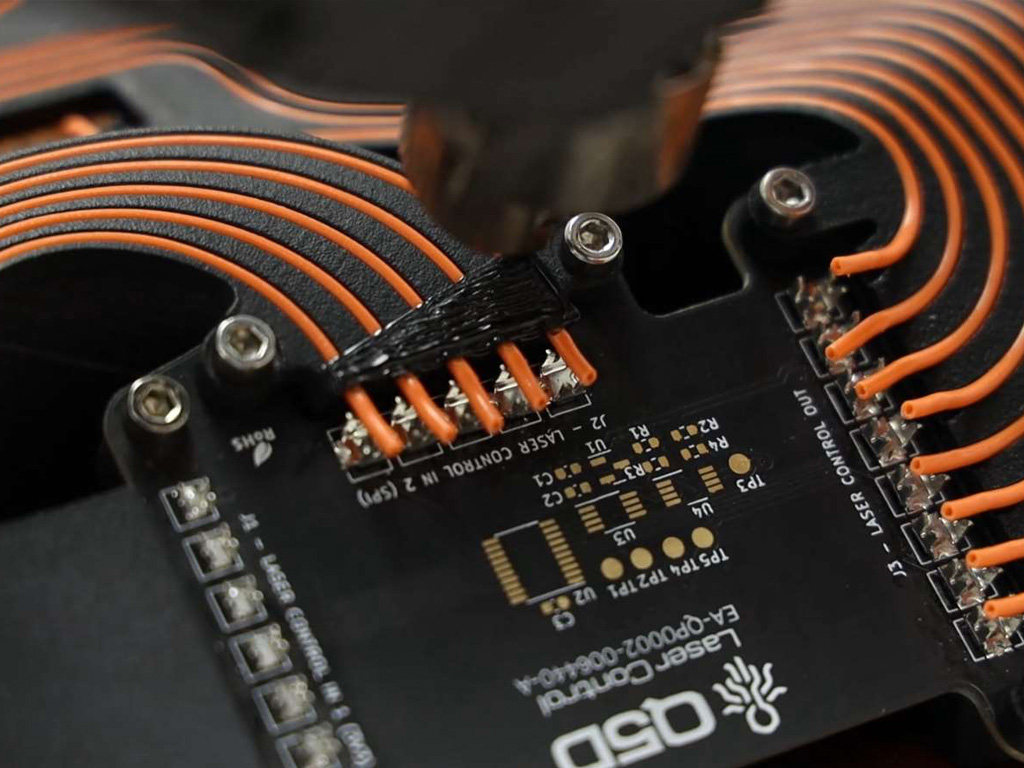

Q5D

Wiring is the critical element that makes so many of modern-day products function. Despite major advances in our approach to these products and their manufacturing, wiring of these products is still made by hand. This renders the wiring process expensive and labor intensive, error prone, leaving us with long and fragile supply chains. Q5D is changing this by combining robotics and AI to add wiring and printed electronics directly into products, thus automating what is currently a manual process.

Their technology yields reduced manufacturing cost, and at the same time improved quality and function. This in turn enables dramatically simplified supply chains, meaning that production can be near-shored. The automotive sector is the first to adopt Q5D’s technology, and in doing so have demonstrated production cost savings of 40%, equivalent to more than $200m annually for each model of vehicle. They have demonstrated product-market fit, with pilot machine sales to some of the world’s largest companies, including Yazaki, Lear, and Jaguar Land Rover, amongst others.